| | start of my rs build |  |

|

|

|

| Author | Message |

|---|

Guest

Guest

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sun Feb 02, 2014 11:38 pm Sun Feb 02, 2014 11:38 pm | |

| - 2ndburn wrote:

- :shock:

Hi DK,

I'm not saying you can't weld Stainless TO mild carbon steel it will be a lovely clean weld and will have nice colours and Damascus looking, nice. BUT the coefficient of expansion is different.

When a mig welder is used with mild steel wire and CO2 & 5% Argon gas mix to weld stainless steel.

And that weld is used in a situation where it is heated up and cooled down over and over in a fire box/riser for example. That weld will definitely be a 100% fail. Because the stainless will expand and shrink more than the mild steel weld will. The weld will crack at the toe of the weld.

Use an Arc welder with stainless rods or. A Tig welder with stainless rod and pure Argon gas. Hello 2ndburn,  I am aware of the different expansion rated of unlike metals when fused together.I also know of written procedures to follow for such welding processes when necessary, to keep from weld failure. I understand, that many of the people building there own RS are not welders or fabricators by trade. So I didn't want to over elaborate and try to make things more confusing then necessary.  Do to the difficulties and increased changes of weld failure, I would never in courage any newbies to weld stainless steel with mig. To much can and does go wrong if your not understanding to the correct procedures to keep from weld failure during the welding process. I was able to find a little info on weld failure that I thought might be helpful for some.  http://content.lincolnelectric.com/pdfs/knowledge/articles/content/weldcracking.pdf http://content.lincolnelectric.com/pdfs/knowledge/articles/content/weldcracking.pdf |

|

| |

2ndburn

Posts : 165

Join date : 2013-12-05

Age : 65

Location : shropshire

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Feb 03, 2014 12:43 am Mon Feb 03, 2014 12:43 am | |

|   Hi DK, I will happily share my knowledge with anyone on this forum that is in need of help with their welding. between the two of us all newbies to welding shouldn't have any problems.   | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Feb 03, 2014 1:41 am Mon Feb 03, 2014 1:41 am | |

| - dkwelder wrote:

- 2ndburn wrote:

- :suspect:

Hi gadily,

When steel heats up it will expand, when steel cools down it contracts. mild steel and stainless steel expand and contract at a deferent rate. Using mild steel to weld stainless steel I think the welds will eventually crack. :(

309L Tig or Stick rod will work well for welding Mild Carbon steel to Stainless Steel. They been doing it for years on different heating and cooling application.   thanks for that i am aware that i need 308L or 308Lsi to weld up with stainless steel 304 as stated by yourself if welding too mild steel then id have to use 309L as i am miging the steels up i have to consider heat as stainless isnt like mild steel and can they buckle and move with the heat - Stainless is easy to weld but very difficult to keep flat, the coefficient of linear expansion is 1.7 times that of mild steel. There isn’t much you can do about that except to weld it quickly and by doing so minimise the heat input. wrote:

the forum has a good guide on this subject http://www.mig-welding.co.uk/stainless.htm | |

|

| |

2ndburn

Posts : 165

Join date : 2013-12-05

Age : 65

Location : shropshire

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Feb 03, 2014 3:20 am Mon Feb 03, 2014 3:20 am | |

|  :| | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 4:55 am Fri Mar 14, 2014 4:55 am | |

| ive been stalling out looking for assistance via the tests that i have done as a newbie i wasnt too sure if i had got the burn vortex right or not however i have gone with 10.3 video than the 15.3 video https://woodstoves.forumotion.co.uk/t302-rs-vortex-testinga little bit more work shaping the stainless steel burn pipe and a slopped vortex tube heres the start 3mm box ive cut into it so i can bend it easier by 1-1.5mm     i havent even tried with secondary air pipe yet so first off build it and weld it up then check your design without secondary air then with secondary air | |

|

| |

2ndburn

Posts : 165

Join date : 2013-12-05

Age : 65

Location : shropshire

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 6:07 am Fri Mar 14, 2014 6:07 am | |

|  Hi Gadily, Looking good! your riser entrance looks a bit small, but "tack" weld it together and then do a test burn. To see if you have the vortex right. Its easer to change if you use small tacks. | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 9:04 am Fri Mar 14, 2014 9:04 am | |

| its part of the reason why i did the test burns via the other pipe and the box i made up to test openings and effects before main build of rs stove

entrance too the vortex pipe is 2 1/4" x 120mm

query thoe does the secondary air have to run in direct line or can it be run via the off shoot as im curious on the difference that it would make however i could test this while building this one up | |

|

| |

2ndburn

Posts : 165

Join date : 2013-12-05

Age : 65

Location : shropshire

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 11:16 am Fri Mar 14, 2014 11:16 am | |

|  Hi, Your secondary air needs to be as hot as possible for it to relight gasses in the riser. you don't want it cooling down. And because hot air rises, it will work best if you put it on a slope up towards the riser. | |

|

| |

T2H

Admin

Posts : 913

Join date : 2013-10-07

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 4:39 pm Fri Mar 14, 2014 4:39 pm | |

| gadily I have used regluar .035 flux core wire and have built three stoves, both having the stainless steel up riser tube welded to the mild steel firebox.

The three different stoves I have used for a full winter three years in a row, I changed the style each year.

I have not seen a single crack or any failure in the welds of all three.

Now I went a bit overboard and did over lap welds, three rows.

Now I do not know the term for that but it held up just fine.

So in theory yes failure for sure, in personal experience I have had no problems.

I will be tearing my third stove apart that I used all winter and will give a report on the weld area where the up riser tube connects to the mild steel firebox.

I plan on using some of the materials for two new stoves I will be building next.

One I plan on using next winter.

The other will be sold.

As well to note, the first two stoves showed no degradation of the steel for the riser tubes, or the firebox.

That was what I found on my first two stoves after using them for an entire winter on two different years and then taking them apart for inspection. | |

|

| |

twistedkarma

Posts : 178

Join date : 2014-01-04

Location : East coast USA

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Fri Mar 14, 2014 8:43 pm Fri Mar 14, 2014 8:43 pm | |

| I believe they used to sell me 310 or 311 to weld steel to stainless.

My steel around my old stove cracked, steel on steel.

it has to do with design, not allways weld.

once you figure out how to beat the odds on that,

then you will realize, out of failures, that some were based on design only, and not weld that accually failed.

Great job on pretesting of risers. , looking forward to end video. | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Mar 17, 2014 6:54 am Mon Mar 17, 2014 6:54 am | |

|

Last edited by gadily on Mon Oct 13, 2014 8:38 am; edited 1 time in total | |

|

| |

Hitchhiker

Posts : 246

Join date : 2013-12-26

Location : nomad

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Mar 17, 2014 11:49 am Mon Mar 17, 2014 11:49 am | |

| I am no expert but that looks good, gadily. | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Tue Mar 18, 2014 3:41 am Tue Mar 18, 2014 3:41 am | |

|

Last edited by gadily on Mon Oct 13, 2014 8:43 am; edited 1 time in total | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Thu Mar 20, 2014 9:21 pm Thu Mar 20, 2014 9:21 pm | |

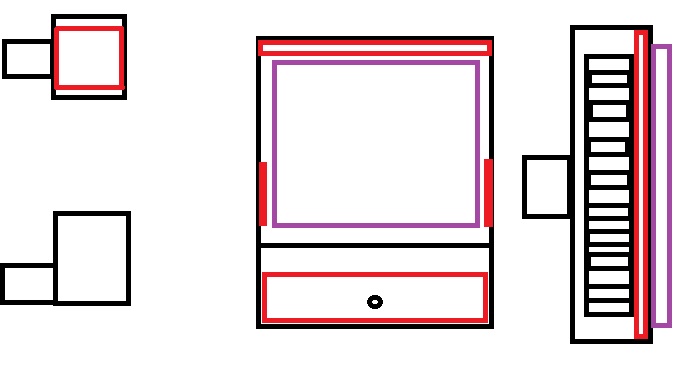

| ive been getting stuff ready while doing other things as well  the green and blue ones is 2 made into one  the 2 red ones are the tops whilst the bottom is made up differently as i was wanting just to slot the top onto a seperate base system | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sat Mar 22, 2014 9:19 am Sat Mar 22, 2014 9:19 am | |

| im waiting for a delivery now of stainless steel sheet 2.5mm for the internals of the burn box then i can finish off the welding the other problem is down to weather too windy to test the correct place for secondary burn and also im curious what would happen if placed on its side would it still have its vortex effect | |

|

| |

caotropheus

Subscribers

Posts : 333

Join date : 2013-10-07

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sat Mar 22, 2014 3:51 pm Sat Mar 22, 2014 3:51 pm | |

| I am enjoying your step by step approach build of your stove. | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sun Mar 23, 2014 12:36 am Sun Mar 23, 2014 12:36 am | |

| - caotropheus wrote:

- I am enjoying your step by step approach build of your stove.

thanks wasnt meant to be that way but as a newbie building one it just has done though on reading and viewing other rs stoves not many show how to build one from scratch and show there testings of the design on most its build it this way only at least this shows why to do it this way but i admit ive thrown in my test as well heres what i will be building once materials arrive  i tested today to find the sweet spot of the secondary air heres the result the lines are for depth inside of the rs stove burner the far right is black as inside the burn box the first line looking at it is outside of the vortex tube the second line is at the edge of vortex tube the adjustments on the 1x1" tube was 1/8th of an inch https://www.dropbox.com/s/n0ux2080zm2175n/VIDEO0019.3gp?dl=0 as you can see the line is behind and i push the pipe further in the first start is just inside the burn chamber as i move it to the line thats level with the vortex tube pushing further in is just inside vortex tube

Last edited by gadily on Mon Oct 13, 2014 8:44 am; edited 1 time in total | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Wed Apr 02, 2014 4:57 am Wed Apr 02, 2014 4:57 am | |

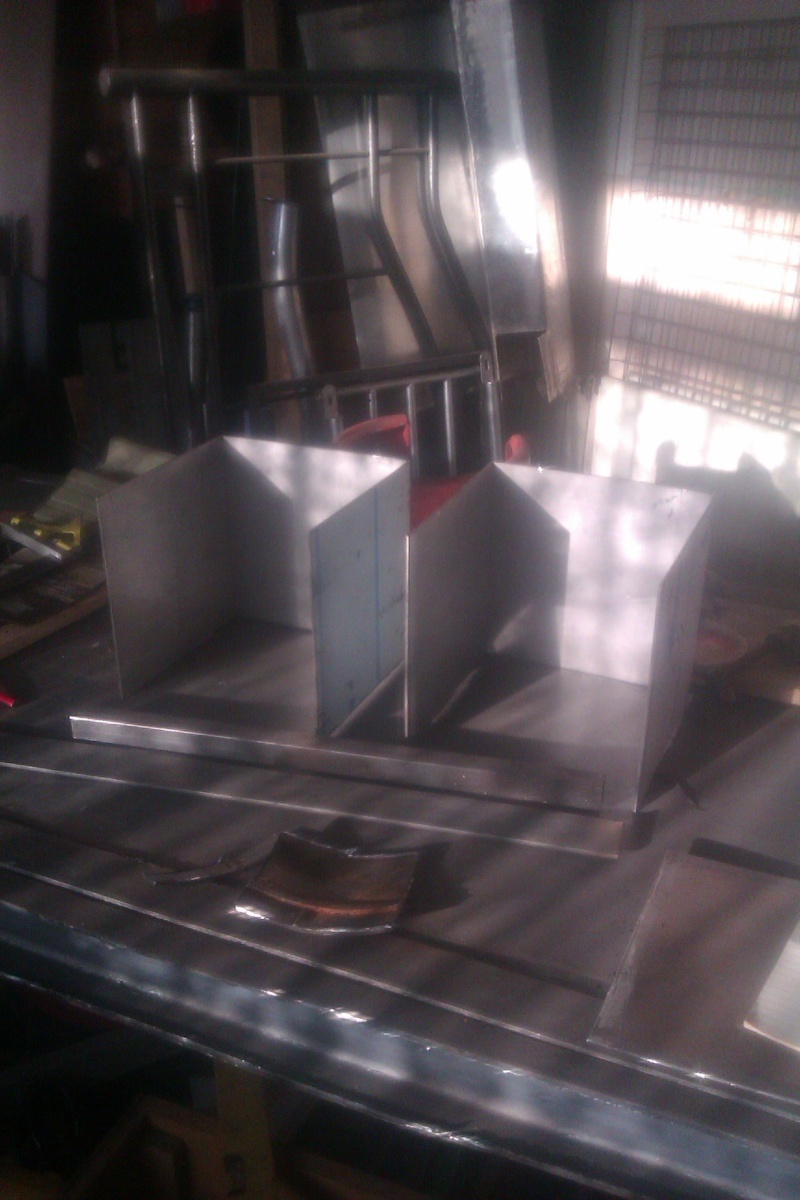

| ive got busy as been pondering how to sort out the burn box and weld it correctly but im also wanting an ash box below it as well in time ive cut my gas bottle down as i want less weight on the bottom design as well as easy access to clean out the rs, as i tend not to like the seal at the top of the rs stove, im also going to put on some handles for easy lift off of the top part   heres the pic of stainless steel burn box pre bent into a u shape and now to weld on the back and inside welding of the box im adding a little more steel to the outside of the stainless steel but the whole burn box is 2.5mm stainless steel  i need the vortex pipe but cant afford one just yet then i can weld up the lot of it in one go | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sat Apr 26, 2014 1:43 am Sat Apr 26, 2014 1:43 am | |

| just had delivery of the secondary air pipe 3mm wall x 1 1/2 as a little bigger im going to have to run a test burn before i weld everything up and call it complete as im doing this over the weekend will post up building pics and the complete build when finished the last thing i will be making is the door and hinges | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sun Apr 27, 2014 5:33 am Sun Apr 27, 2014 5:33 am | |

| heres the update ive used the 3mm ss with this build as im making ppottys jtube version but smaller  metal trim tacked on  pipe seems to be offside leaning  the internal view of secondary burn chamber with 3mm stainless steel pipe as seen  updated the burn box, burn chamber and the vortex tube are all stainless steel ( ss ) after this its swapped back to 3 mm steel for tubing and 5 mm steel for the top surface https://www.dropbox.com/s/907cvy10bi78v84/VIDEO0052.3gp?dl=0chimney still to go in and finish the welding off need some high temp silicone and also fire rope to seal up the last thing to make up is the sides top and lid of the burn box

Last edited by gadily on Mon Oct 13, 2014 8:45 am; edited 1 time in total | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sun May 11, 2014 3:46 am Sun May 11, 2014 3:46 am | |

| an update curved the external flick plates the other build is a downdraft system that im building out of scrap to test  unwelded top of burnbox  steel scrap welded to top 5mm steel bars welded inside and out  welded up just need to weld outer to stainless steel inner  next is build door but i have only an oven glass and im considering an ash box below and i so like the twist closers so cut out 2" hole in side steels | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Tue Jun 10, 2014 5:58 am Tue Jun 10, 2014 5:58 am | |

| had a problem with this as it was too small in height so had to change it back to a standared 30"+ system https://woodstoves.forumotion.co.uk/t395-help-needed-with-small-build-rsit is now complete and tested these are the new pics and vids to go with it just quick tested this much better pull on the burn box now height of gas bottle from floor 34" high 24" vortex pipe repaired pipe some may say bodged but its my tester and im keeping it, vortex pipe is 2" short of the top cap but i can trim down on the bottle lowering the height  again tested after cutting the gap down to 10mm for glass air wash as wasnt happy with the tar effect with other tests sorry it goes upside down https://www.dropbox.com/s/av6jpjqew3wacfz/20140607_212922.mp4https://www.dropbox.com/s/gwoem3ajmpd3nhe/20140607_213902.mp4https://www.dropbox.com/s/8hkduthyuy5ryhp/20140607_214350.mp4decided to fill it up even thoe using normal safety glass https://www.dropbox.com/s/gh3ad52ic58gckk/20140607_215100.mp4ive had it that hot the top was melting the paint off and back of it was going black with heat the exhaust pipe was red hot to the touch you may notice the taring on the glass is much lesser now since the change theres one more test im going to do now and thats with some oak beam wood i can get from an old factory though i know they could have been coated from the old wool days on them ive ordered the last of the parts i need stove glass that was expensive found a cheaper source instead 1500c silicone i didnt think the 300c silicone was adequate 10mm door rope i will use the silicone to stick it to the surface of the door and make the door for the stove glass as can make it to fit the glass ive bought | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Oct 13, 2014 10:38 am Mon Oct 13, 2014 10:38 am | |

| | |

|

| |

caotropheus

Subscribers

Posts : 333

Join date : 2013-10-07

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Mon Oct 13, 2014 2:00 pm Mon Oct 13, 2014 2:00 pm | |

| The project is advancing nicely. When I use the thermometer I try to keep the laser as close as possible to 90 degrees in relation to the surface. I think it will give you more accurate readings. Also the distance from the surface may influence the readings, so I try to keep about 30 cm from the surface I want to measure the temperature.

I could notice as well that when you light the stove, you insert some fuel through the square pipe that goes from the fuel/combustion chamber to the riser tube. If you just light the fuel/combustion chamber and close the glass door/window the stove will not work? If all the passages to the riser tube are clear and not obstructed the stove will work better, right? | |

|

| |

gadily

Moderator

Posts : 1477

Join date : 2013-12-08

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  Sat Dec 27, 2014 3:18 am Sat Dec 27, 2014 3:18 am | |

| an update on its weight with my rocket stove minus the heat wrap i havent installed as of yet 46kgs  | |

|

| |

Sponsored content

|  Subject: Re: start of my rs build Subject: Re: start of my rs build  | |

| |

|

| |

| | start of my rs build |  |

|